Manufacturing Automation Case Study: Transforming from Manual to Smart Factory

- Platform Category:

- Industrial IoT (IIoT) Platform

- Core Technology/Architecture:

- Edge Computing and Real-time Data Streaming

- Key Data Governance Feature:

- Asset-Based Access Control and Data Lineage

- Primary AI/ML Integration:

- Predictive Maintenance Models and Anomaly Detection

- Main Competitors/Alternatives:

- Siemens MindSphere, Microsoft Azure IoT, AWS IoT, PTC ThingWorx

The journey from a traditional manual production line to a fully integrated smart factory is a testament to the power of Manufacturing Automation. This transformation is no longer a futuristic concept but a vital strategy for industries aiming to optimize operations, enhance output, and maintain a competitive edge in today’s fast-evolving market. Our focus here is on understanding a real-world transition, examining how a facility moved from manual processes, which were prone to human error and struggled with scalability, to an advanced automated system, thereby making a compelling case for fundamental change.

Introduction: The Imperative of Manufacturing Automation

In an era defined by rapid technological advancements and fierce global competition, the manufacturing sector stands at a critical juncture. The shift from manual labor to sophisticated, automated systems is not merely an upgrade; it’s a fundamental paradigm shift enabling unprecedented levels of efficiency, precision, and innovation. This deep dive explores a compelling case study of a manufacturing entity that successfully navigated this complex transition, leveraging advanced Manufacturing Automation to evolve into a highly efficient smart factory. By dissecting their journey, we aim to uncover the strategic decisions, technological implementations, and tangible benefits that define such a transformative endeavor. Understanding this shift provides invaluable insights for other organizations contemplating their own digital transformation within the industrial landscape.

Core Breakdown: Architecture and Implementation of a Smart Factory

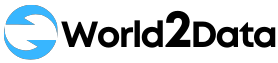

The transformation into a smart factory is underpinned by a meticulously planned architectural overhaul, moving away from disparate systems to an integrated, data-driven ecosystem. At its heart lies an Industrial IoT (IIoT) Platform, serving as the central nervous system that connects every machine, sensor, and system across the production floor. This platform facilitates seamless data acquisition and communication, which is crucial for modern Manufacturing Automation.

A cornerstone of this architecture is Edge Computing. Sensors and controllers at the ‘edge’ of the network — directly on the factory floor — process data locally and in real-time. This reduces latency, conserves bandwidth, and enables immediate decision-making for critical tasks, such as robotic movements or quality control adjustments. Alongside edge computing, Real-time Data Streaming ensures that operational insights are continuously available. Data from hundreds, if not thousands, of IoT sensors, PLCs, and SCADA systems flows into data pipelines, providing an up-to-the-second view of production status, machine health, and resource utilization. This continuous feedback loop is vital for responsive and adaptive manufacturing processes.

For a smart factory to operate effectively, robust data governance is paramount. The implemented solution features Asset-Based Access Control, ensuring that data access is granted only to authorized personnel or systems based on their roles and the specific assets they manage. This granular control is critical for security and compliance. Furthermore, comprehensive Data Lineage tracks data from its origin (e.g., a specific machine sensor) through every transformation and analysis step. This transparency is invaluable for auditing, troubleshooting, and maintaining data quality, which directly impacts the reliability of automated systems.

The primary AI/ML integration within this smart factory revolves around two critical applications: Predictive Maintenance Models and Anomaly Detection. Predictive maintenance uses machine learning algorithms to analyze real-time sensor data (vibration, temperature, current, acoustic signatures) to forecast potential equipment failures before they occur. This proactive approach drastically reduces downtime, extends asset lifespan, and optimizes maintenance schedules. Anomaly detection, on the other hand, monitors operational parameters to identify unusual patterns that might indicate a deviation from normal operations – be it a malfunctioning component, a quality issue in a product batch, or a security breach. These AI/ML capabilities are fundamental to the resilience and efficiency of advanced Manufacturing Automation.

Challenges and Barriers to Adoption in Manufacturing Automation

The transition to a smart factory, while offering immense potential, is not without its hurdles. One of the primary challenges is the sheer complexity of integrating disparate legacy systems with new IIoT platforms and AI/ML models. Many existing factories operate on decades-old infrastructure, and achieving seamless interoperability requires significant investment in middleware and integration expertise. Data security and privacy are also paramount concerns; connecting operational technology (OT) with information technology (IT) networks expands the attack surface, necessitating robust cybersecurity measures to protect sensitive production data and intellectual property. Furthermore, managing the vast volumes of data generated by IIoT devices, ensuring its quality, and processing it efficiently for real-time insights presents a substantial data management challenge. Workforce reskilling is another critical barrier; the shift from manual labor to overseeing automated systems requires new skill sets in data analytics, robotics programming, and IT management, often leading to a significant learning curve for existing employees.

Business Value and Return on Investment (ROI) of a Smart Factory

Despite the challenges, the business value delivered by advanced Manufacturing Automation and a smart factory model is profound. The most immediate impact is a dramatic increase in operational efficiency, often leading to reduced cycle times and higher throughput. Automated systems perform tasks faster and with greater precision than human operators, minimizing errors and rework. This directly translates into significant cost reductions in labor, waste, and energy consumption. Predictive maintenance, powered by AI, transforms maintenance from a reactive, costly affair into a proactive, optimized process, leading to fewer unplanned downtimes and extended equipment lifespans. The enhanced data visibility provides management with real-time insights, enabling more informed and agile decision-making across the entire value chain. Improved product quality, driven by AI-powered quality inspection systems, leads to higher customer satisfaction and reduced warranty claims. Ultimately, these benefits culminate in a stronger competitive position, faster time-to-market for new products, and a substantial return on investment (ROI) that extends beyond mere cost savings to encompass innovation and market leadership.

Comparative Insight: Smart Factory vs. Traditional Manufacturing

To truly appreciate the advancements brought by Manufacturing Automation, it’s essential to contrast the smart factory model with traditional manufacturing paradigms. A traditional factory typically operates with manual labor dominating production lines, relying on human operators for repetitive tasks, quality checks, and equipment monitoring. Data, if collected, is often siloed, fragmented, and analyzed retrospectively, leading to reactive decision-making. Maintenance schedules are usually time-based or reactive, resulting in unpredictable downtime and higher operational costs.

In contrast, a smart factory represents a fundamental shift in philosophy and execution. It is characterized by pervasive connectivity through IIoT, enabling every machine, tool, and even product to communicate and share data in real-time. This interconnectedness allows for truly holistic visibility across the entire production process. Where traditional factories struggle with scalability and flexibility, smart factories leverage robotics, AI, and modular production units to adapt quickly to changing demands and product variations. Manual quality control is replaced by AI-powered vision systems, offering consistent, high-speed inspection. Furthermore, the reliance on human intuition and experience for operational adjustments is supplanted by data-driven insights and predictive analytics, optimizing everything from energy consumption to inventory levels.

The data architecture itself is vastly different. Traditional setups might use basic SCADA systems or isolated databases. A smart factory, however, integrates an IIoT platform with edge computing for local processing, cloud platforms for deeper analytics, and sophisticated data lakes or warehouses to store historical and real-time data. Data governance, including asset-based access control and detailed data lineage, ensures the integrity and security of this critical information flow, which is often an afterthought in older systems. The transition from a reactive, human-centric model to a proactive, data-driven, and highly automated system marks a monumental leap in industrial productivity and efficiency, embodying the true spirit of Industry 4.0.

World2Data Verdict: The Unstoppable Momentum of Smart Manufacturing

The case for comprehensive Manufacturing Automation, as demonstrated by the successful transition to a smart factory, is unequivocal. The continuous drive towards hyper-connectivity, intelligent systems, and data-driven decision-making represents not just an evolution but a necessary revolution for industries striving for global competitiveness. World2Data.com believes that the future of manufacturing lies firmly in the hands of technologies like IIoT, Edge Computing, and advanced AI/ML for predictive maintenance and anomaly detection. Organizations that embrace these core technologies, coupled with robust data governance frameworks like asset-based access control and data lineage, will not only survive but thrive. The competitive alternatives like Siemens MindSphere, Microsoft Azure IoT, AWS IoT, and PTC ThingWorx underscore the intense innovation in this space, offering diverse paths to achieving smart factory goals. For any enterprise looking to bolster operational efficiency, enhance product quality, and secure a sustainable competitive advantage, investing in and strategically deploying Manufacturing Automation is no longer optional; it is the definitive pathway to unlocking unprecedented levels of industrial productivity and resilience.